Products

- Rubber Mixing Mill

- Rubber Mixing Mill with Stock Blender

- Cold Feed Rubber Extruder

- Hot Feed Rubber Extruder

- Dispersion Kneader

- Co-Extruder

- Rubber Calender Machine

- Rubber Moulding Hydraulic Press

- Rubber Bale Cutter

- Vulcaniser / Auto Clave

- Reclaim Machinery

- Silicon Rubber Extruder

- Pin Barrel Rubber Extruder

Online Quote

Please fill the below form to get an

online quotation.

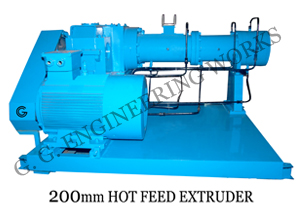

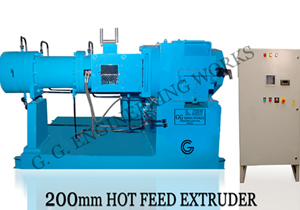

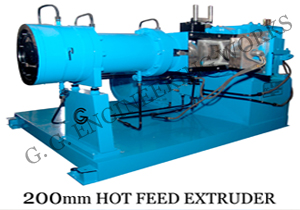

Hot Feed Rubber Extruder

“G. G. Hot Feed Extruders” are ideally suited for production of Rubber Chords, Rubber Strips, Rubber Profiles, Rubber Tubing, Rubber Channels, Rubber Treads and are Specially designed for meeting the need for efficient and quality extrusions.

G. G. Engineering Works based in Mumbai, India, offers a vast range of Hot Feed Rubber Extruders in size 40, 56, 63, 75, 100, 110 & 150 mm or different applications, such as Tread, Tubes, Profiles, Hoses, Sheeting with Roller die head, Cable coating, Dock Fenders, Straining of Raw materials, Press blanks, pre-warming for Calendar feeding, Inner tubes for Bicycle, cars and Trucks.

Manufacturers of Hot Feed Rubber Extruder Mumbai India

L/D Ratios : 4:1/ 6:1/8:1

MATARIAL FEED : Tangential under cut Hopper & Feed Roll Device.

DRIVES : Constant Speed or variable speed.

HEADS :

STRAIGHT HEADS for Tube, Profile, Rods etc.

CROSS HEAD for second coating of pre-extruded section like Hoses, Profile etc.

STRAINER HEADS for filtering the compounds.

TREAD HEADS for Treads & Camel - back.

CO-EX HEADS for extruding multiple components in one go.

TEMPERATURE CONTROL: Standard offers are with manual temperature control with valve opening/closing, whereas as in case of accurate temperature control requirement high pressure close loop thermo-fluid circuits with Electrical Heaters & pumps can be offered to control the temperature in ±1oC

ACCESSORIES: (OPTIONAL) Talcum unit, Post Extrusion Conveyors, Roller Die Head Units, Spray Coolers, Strip Winders, Blank storing Circular trays can be offered at extra cost.

FEATURES of Hot feed rubber extruder:

- Equipped With Hardened Feed Roller For Accurate & Consistent Feeding of Rubber Strips inside the extruder.

- This Helps in Maintaining consistent Extrusion Pressure Resuting in High Quality Extrusions.

- Equipped With Water Circulations Systems Through Rotary Pressure Joints.

- Feeding arrangement with spiral undercut and feed roll arrangement provided which ensures a proper bite & strip fed to screw.

Rubber Extruder

We can provide any machine in a specific time to customers based in India as well as any part of the world as we have our manufacturing facility in Mumbai which is the commercial capital of India.

A Special type 115 mm hot feed Rubber extruder with hinged type quick locking Strainer and Tube Die Head with feed roll attachment having 2 heads- hinged type, one for straining purpose and other for Tube extrusion. Quick locking arrangement helps in changing the straining mesh with ease .

Model |

Screw Diameter | L/D Ratio - 4:1 |

L/D Ratio - 5:1 6:1 with

Feed Roll |

L/D Ratio - 8:1 with Feed Roll | |||||||

Scroll RPM |

Electric Motor | Output | Scroll RPM | Electric Motor | Output | Scroll RPM | Electric Motor | Output | |||

| INCH | MM | RPM | HP | KG/HR | RPM | HP | KG/HR | RPM | HP | KG/HR | |

GGEX-55 |

2 |

55 |

36 |

5 |

30 |

# |

# |

# |

48 |

7.5 |

45 |

GGEX-63 |

2.5 |

63 |

36 |

7.5 |

50 |

# |

# |

# |

# |

# |

# |

GGEX-75 |

3 |

75 |

36/48 |

10 |

75/90 |

# |

# |

# |

48 |

15 |

115 |

GGEX-90 |

3.5 |

90 |

EXCLUSIVELY FOR SEALANTS WITH DOUBLE FEED ROLLER |

48 |

30 |

180 |

|||||

GGEX-100 |

4 |

100 |

36 |

15 |

150-175 |

36/48 |

15/25 |

200/240 |

# |

# |

# |

GGEX-115 |

4.5 |

115 |

36/48 |

20/30 |

250/300 |

# |

# |

# |

# |

# |

# |

GGEX-150 |

6 |

150 |

36 |

40 |

275-350 |

40 |

60 |

350-500 |

# |

# |

# |

GGEX-200 |

8 |

200 |

33 |

100 |

750 |

33 |

125 |

800-950 |

# |

# |

# |

GGEX-250 |

10 |

250 |

# |

# |

# |

27/43 |

120/200 |

1800/3000 |

# |

# |

# |

FOR FEEDING - ALL EXTRUDERS ARE HAVING HOPPER WITH SPIRAL UNDERCUT |

|||||||||||

FOR COOLING & HEATING - BARREL JACKETED IN SINGLE ZONE & DOUBLE ZONE |

|||||||||||

FOR ALL EXTRUDERS - STANDARD ADAPTER HEAD ARE PROVIDED OTHER HEADS ARE OPTIONAL |

|||||||||||

| NOTE :- # CAN BE MADE AS PER CUSTOMERS SPECIFICATION | |||||||||||